Case Study

Bakken Operator Slashes $1.7 Million in First-Year OPEX with SureLaunch®

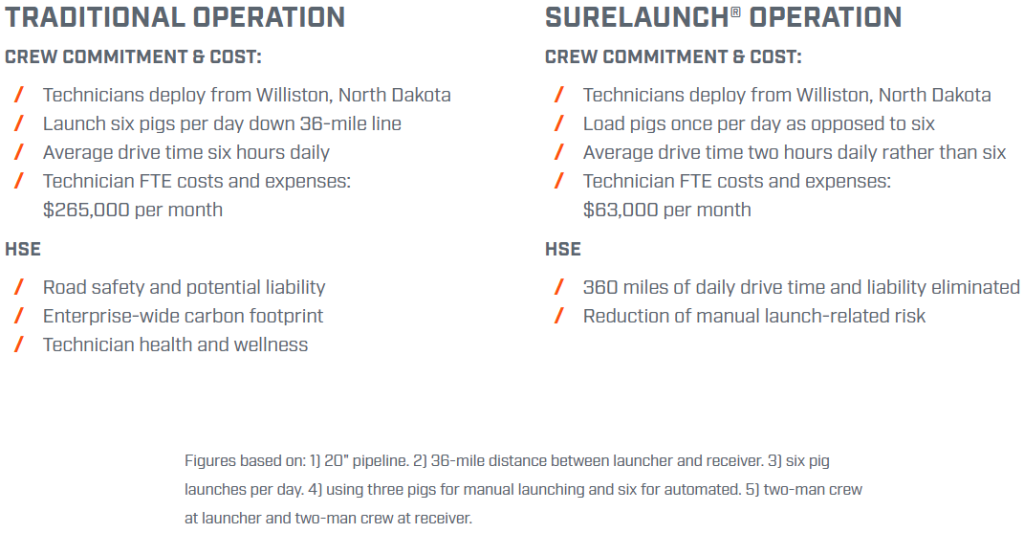

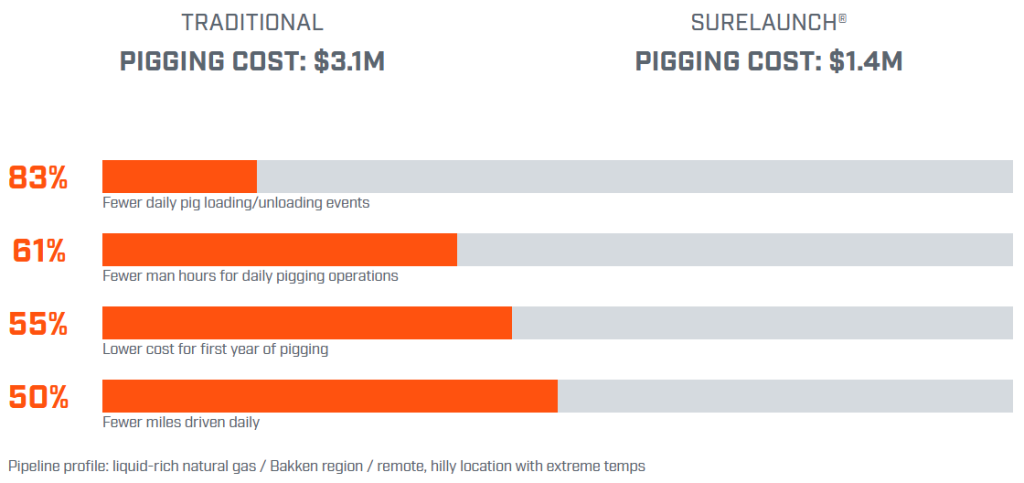

With remote distances and a liquids-rich natural gas line necessitating frequent pigging, this pipeline operator wanted to streamline its pigging program in North Dakota to maximize value for unit holders. The system in question is a 36-mile stretch of 20” line connecting a gathering system to a processing facility in Western North Dakota.

The line requires pigging six times daily. Its manual deployment system required technicians to be employed full-time to make three trips up the line and back each day. In addition to the significant expense and crew utilization constraints, the region experiences extreme weather and is a hazardous place to drive five months out of the year.

Upgrading to a SureLaunch® system enabled the operator to launch up to seven pigs automatically at set intervals without a manual reload per single pig launch, which necessitated only one trip up the line each day rather than three.

This upgrade allowed the customer to:

- Reduce program operating costs in the first year by more than $1.7 million with a projected annual OPEX savings of more than $2.4 million in years two through five

- Free up 2/3 of the technicians’ time for more value-added duties

- Reduce crew costs based on overall utilization

- Minimize the program’s carbon footprint through reduced drive time and less frequent opening/closing of launcher and receiver

- Slash driver liability risk and help keep the technicians safe by cutting drive time associated with pigging operations from six hours to just two each day