In-Service Welding

FOR IN-SERVICE WELDING – EXPERIENCE MATTERS

Welding hot tap and line stop fittings onto a pressurized pipeline is complex and potentially risky, and not every welder is qualified — but our in-service welders are.

Each of our welders has more than two years of in-service welding (ISW) experience, as well as an average of 10 years of general experience in welding in the oil and gas industry. That means they’ve seen it all, understand the safety, technical, environmental, operational and regulatory factors that affect ISW and know how to overcome perplexing challenges.

Read More

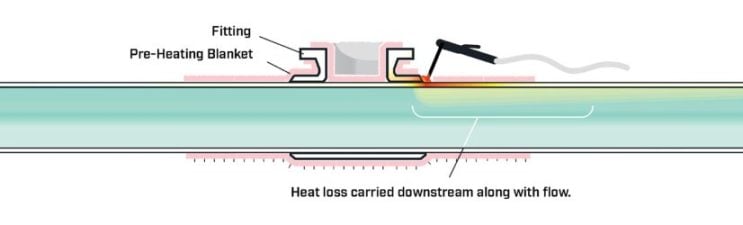

In-service welding (ISW) in high-flow applications presents unique challenges. Product flowing through the pipeline system at a high volume affects both heat dispersion and cooling rates, making the management of heating and temperatures more complex than usual.

WeldFit has developed specialized welding procedures to deliver successful, durable welds in high flow pipelines of any size. Using advanced techniques, we can manage heat dispersion and temperature fluctuations, without reducing pressure or flow rates.

Read More