Case Study

PIPELINE OPERATOR STREAMLINES ILI TOOL RUN WITH ReCAP™

As is the case with many ILI tool runs, maintaining a constant tool speed through the pipeline is critical to obtaining accurate data readings. The more the tool speed varies throughout the run, the more difficult it is for the tool’s sensitive data collection and measurement devices to pick up critical pipeline anomalies. Likewise, varied tool speeds make it more difficult for data analyzers to piece together information about the pipeline.

In central Iowa, the nation’s largest interstate natural gas pipeline owner and operator needed a way to control the speed of their inline inspection tool to obtain the most accurate data about their 16” pipeline the first time.

While there are many common pipeline variables — obstructions, debris and tight bends — that affect ILI tool speed and are virtually impossible to control, gas flow rate is one variable that, with the right solution, can be controlled.

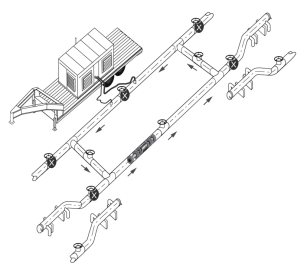

To do this, WeldFit deployed its ReCAPTM mobile cross compression technology to help our customer achieve predictable results during their ILI tool run. ReCAP is already widely accepted in the industry as a methane-reduction solution that depressurizes isolated pipeline sections by recapturing and recompressing gas for reinjection into live pipelines.

On this project,  ReCAP was applied in a similar way albeit to control the gas flow rate which, in turn, controlled the customer-specified ILI tool speed. Upon the launch of the ILI tool, ReCAP was placed in service and began pulling gas at a constant rate out of the pipeline in front of the ILI tool, which decreased pressure in front of the tool. Once recompressed, ReCAP discharged the gas through a pressure regulator and reinjected it at a constant pressure into the pipeline behind the tool.

ReCAP was applied in a similar way albeit to control the gas flow rate which, in turn, controlled the customer-specified ILI tool speed. Upon the launch of the ILI tool, ReCAP was placed in service and began pulling gas at a constant rate out of the pipeline in front of the ILI tool, which decreased pressure in front of the tool. Once recompressed, ReCAP discharged the gas through a pressure regulator and reinjected it at a constant pressure into the pipeline behind the tool.

By controlling the gas flow rate, ReCAP helped maintain a constant pressure differential across the ILI tool, which helped the tool maintain a consistent speed throughout the run.

By utilizing ReCAP to control the gas flow rate and ILI tool speed, our customer was able to collect accurate pipeline data after only one tool run. The customer avoided the need for additional costly and time-consuming tool runs and data analysis exercises, which can add tens of thousands of dollars and weeks to a project’s budget and schedule.

Information required to prepare a quote includes but is not limited to the following:

- ILI tool data sheet

- Target speed (mph) for ILI tool

- Information about where supply gas for compression will come from as well as where compressor discharge gas will go

- Suction Pressure (psig)

- Discharge Pressure (psig)